- It means choosing a company that is rooted in its local area, fully aware of its responsibilities and concerned about its environmental and economic ecosystems.

- It’s buying French

- It means working with one of the only French companies to integrate all manufacturing on a single site: from the steel coil to the mast delivered to your worksite.

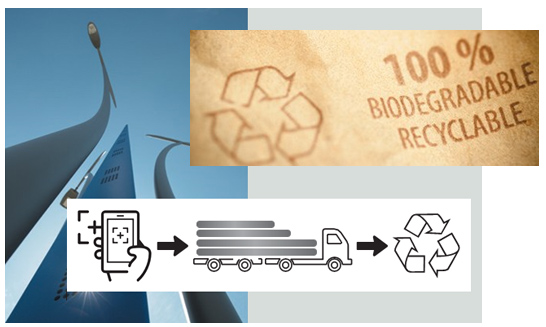

Less transport, less transfer means less CO2!

Nous ne faisons pas que planter des arbres, nous agissons !

A strategic choice underpinned by conviction

It’s easy to unburden yourself and buy a good conscience:Compensating for carbon -> while -> not seeking to combat its emissions

Outsourcing activities – > in -> not monitoring its subcontractors

Buying rights to pollute – > while -> creating competitive distortions

Shirking responsibility – > while -> manufacturing where standards are least stringent

Reduce costs – > while -> buying at the lowest price

In a nutshell, subcontracting allows us to free ourselves from the problems of our responsibilities and to present a green balance sheet at a lower cost. For many years now, the France Galva Group has been implementing a continuous process to improve its environmental impact and rigorously monitor current standards. Each site, whether it employs 20 or 250 people, includes a Quality, Safety and Environment manager on its management team, so that local issues can be closely managed.

The head office support team is made up of 5 people.

our mast production line

1. Steel coils

The steel comes from Arcelor Mittal or its French subsidiaries 2 (sources: supplier rules and commitments).

2. peeling levelling

The use of superior S235 and HLE steels makes it possible to limit the weight of products by working on the thickness and conicity of masts for very demanding weights and wind zones.

3. slitting

Computer-aided design and drafting systems optimize dimensions to limit waste and scrap (profitability and price).

4. trapezius cut

Conimast is equipped with an automated line to remove the base and top slants of the masts to limit rework and scrap.

5. Bending / robotic line

Conimast is equipped with an automatic, robotized folding machine for greater repeatability and staff safety.

The company uses the services of various recycling companies: .

Pour les chutes d’acier : DERICHEBOURG (89) .

Pour les huiles hydrauliques : Sté YONNE RECYCLAGE (89) . For solvents : SARP INDUSTRIE (78) Conimast has a Yaskawa robotic line.

6. welding (Chrome 6 banned from process)

By joining and melting filler metal without filler metal (plasma technology) 6 Or by joining and filler metal (submerged flux technology).

Welding rework.

Welding wire supplier: SAF – Air Liquide.

We invest for a clean and responsible industry

1. Our galvanizing units are equipped with anti-pollution and water treatment stations.

2. All our galvanizing units are equipped with fume extraction systems.

3. Sanding areas are equipped with dust extraction to remove zinc dust.

our ambitions for tomorrow

Act with us

1. RECOVERY OF END OF LIFE MASTS BY APPOINTMENT We want to use the return of our delivery rounds to set up a real recycling channel for end-of-life masts.

A telephone number will be affixed to the masts to signal the request for collection at a grouped point.

2. ELIMINATING NON-RECYCLABLE WASTE FROM OUR PACKAGING.

Transport fabrics are already made from recycled and recoverable materials.

.

Replacement of PE corner protectors with recycled and recyclable cardboard.