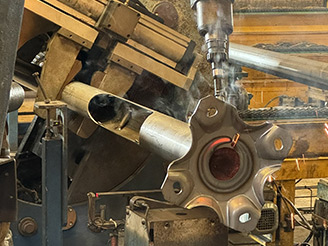

Raw steel for your candelabra

Conimast International has the unique advantage of grouping the entire manufacturing process on a single site, which means less transport and therefore less carbon footprint, from the roll of sheet metal to the painted mast ready for delivery! With expertise in all the trades, you can be sure of the responsibility of a single manufacturer.

Galvanizing process

Hot-dip galvanizing to standard NF EN ISO 1461 is a process for protecting steel against corrosion by immersing it in a bath of molten zinc.

The zinc reacts with the steel to form a protective layer that prevents oxidation.

This coating offers enhanced durability and strength, extending the life of metal structures.

Powder coating

A paint coating on hot-dip galvanized steel is primarily for aesthetic purposes, although the combination of the two processes makes for a more durable fitting, especially for paint.

As the steel substrate is protected, rust cannot attack it or lift the coating from beneath.